Showroom

Multi ribbed belts, also known as

serpentine belts or ribbed V-belts, are specialized belts with multiple

longitudinal ribs on their inner surface. They offer increased power

transmission capacity, improved grip, and reduced slippage, making them ideal

for high-speed and high-torque applications in automotive engines, industrial

machinery, and appliances.

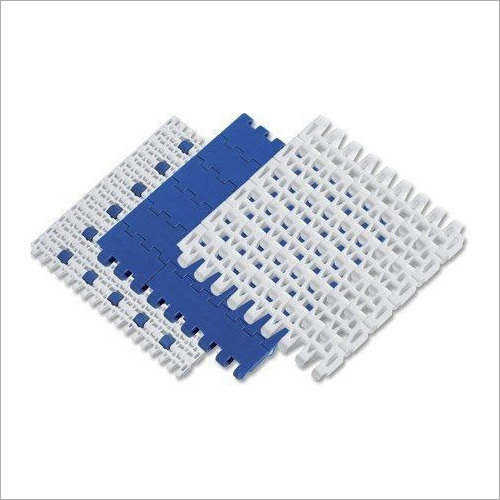

Modular belts are versatile conveyor belts

consisting of interlocking plastic or metal modules. They provide a flexible

and customizable solution for various conveying applications, offering benefits

such as easy maintenance, efficient product handling, and the ability to handle

complex shapes and sizes.

Conveyor belts are essential in various

industries for efficient material handling and transportation. They consist of

a continuous loop of durable material, allowing for the movement of items or

bulk materials. Conveyor belts enable automation, streamline processes, and

enhance productivity in manufacturing, logistics, mining, and other sectors.

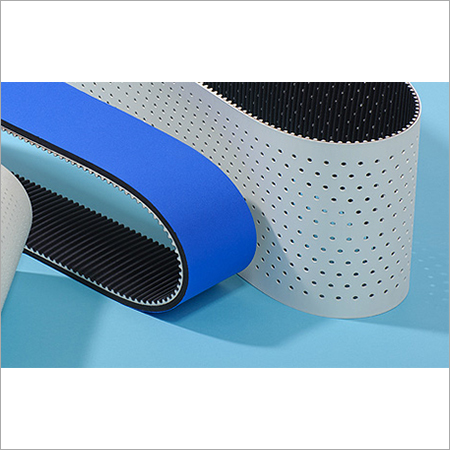

A vacuum-coated belt is a specialized belt

that undergoes a vacuum-coating process, where a thin layer of material is

deposited onto its surface. This coating enhances the belt's properties, such

as increased durability, improved friction resistance, or added conductivity,

depending on the desired application.

A perforated coated belt is a specialized

belt that features evenly spaced perforations or holes across its surface. This

design allows for enhanced airflow, drainage, or filtration in applications

such as conveyor systems, sieving, or separation processes where airflow or

liquid passage is required.

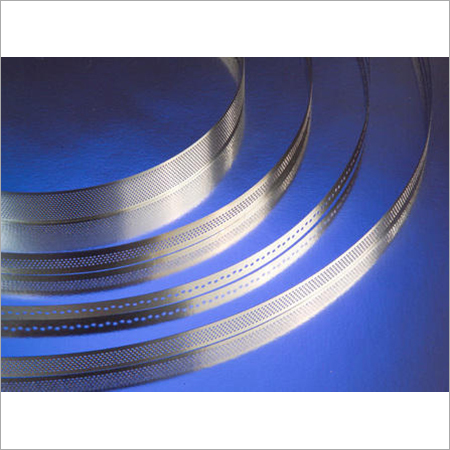

A heat-sealing steel belt is a specialized

belt made of steel that is used in heat-sealing applications. It offers

excellent heat conductivity and durability, making it ideal for sealing

processes in packaging, food processing, and manufacturing industries.

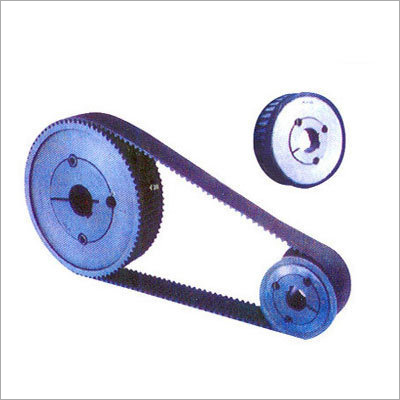

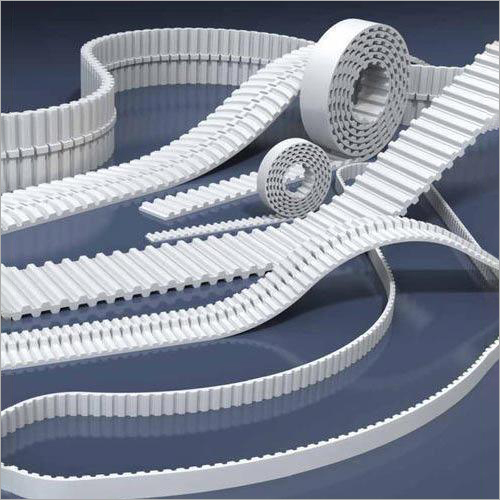

An industrial timing belt is a power

transmission belt used in various industrial applications to synchronize the

movement of two or more rotating shafts. It features teeth or grooves on its

inner surface, providing precise and reliable power transmission, ensuring

accurate timing and efficiency in machinery and equipment.

A double-sided timing belt is a specialized

belt that features teeth or grooves on both sides, allowing for power

transmission and synchronization from both surfaces. This design offers

increased flexibility and versatility, making it suitable for applications that

require bidirectional power transmission or multiple shaft connections.

An HTD timing belt is a type of toothed

belt commonly used in power transmission applications. It features a

curvilinear tooth profile that provides efficient torque transfer, high

load-carrying capacity, and reduced noise compared to other belt types, making

it suitable for demanding industrial applications.

A machine timing belt is a crucial

component used in machinery to synchronize the rotation of different parts. It

ensures precise timing and coordination between components, allowing for smooth

and efficient operation. Machine timing belts are commonly found in various

industries, including manufacturing, automation, and robotics.

Vaccum timer belt is a component used in

vacuum systems to measure the duration of vacuum cycles. It ensures precise

timing for processes requiring vacuum pressure, contributing to accurate and

efficient operation in various applications.

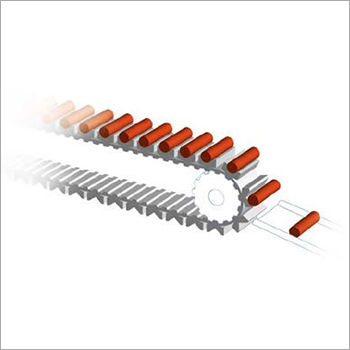

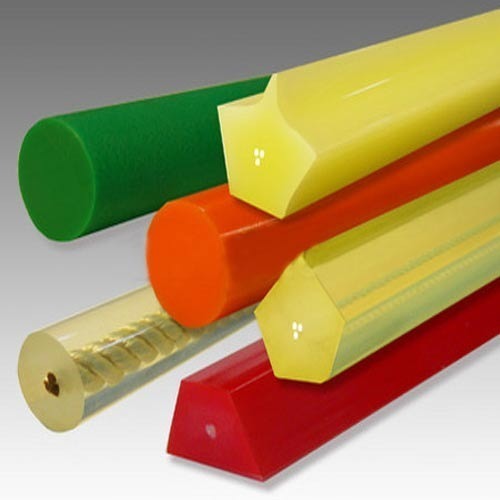

Power twist link V belts are innovative,

adjustable, and easy-to-install power transmission belts. They feature

interlocking links that provide flexibility in length adjustment without the

need for tools. These belts offer reliable performance, reduced downtime, and

efficient power transfer in various industrial applications.

|

SHREYA INTERNATIONAL

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry